Diamond C Trailers is a family-owned and operated trailer manufacturer located in Mt. Pleasant, Texas and has been manufacturing high quality trailers for 35 years. Flaman's Diamond C lineup includes utility trailers, hydraulic dump trailers and equipment and machinery flat deck trailers.

But what makes Diamond C’s trailers different?

ENGINEERED BEAM TECHNOLOGY

Diamond C engineers I-Beams, optimizes them and then builds specifically for each trailer configuration, just like the semi-trailer manufacturers have been doing for decades. These engineered I-Beam frames are taller, stronger, and lighter than the industry standard for deck-over and flatbed trailers.

Depending on the model, the beams on gooseneck trailers range from 14-18″ tall, and the beams on compatible dump and equipment trailer models range from 10-12″ tall. Standard steel will buckle and break at 36 ksi, and the beams are built using steel rated at 50 ksi minimum, so it springs back no matter what load you put on it.

Diamond C FMAX216 Gooseneck Trailer with 18″ Engineered Beam

Diamond C Heavy Duty Low Profile Dump Trailer

THE CAMBER

The deck and frame have a slight camber when not loaded. When loaded, it flexes as necessary to level but never sags like traditional goosenecks do.This helps secure the load and prevents your load from swaying.

Model FMAX307 Gooseneck Trailer

ENGINEERED NECK

You’ll notice our goosenecks look very different than normal flatbed gooseneck trailer necks do. This is by design. Our curved 12″ Engineered Neck design distributes force throughout the neck so there is no concentration of stress in the corners like on traditional goosenecks. These Engineered Necks come standard on any gooseneck Fleetneck series trailer, and well as on most of our bumper-pull trailers featuring our optional Gooseneck package upgrade.

Check out the neck stress test flyer below, which compares the Diamond C Engineered Neck with a traditional I-Beam neck on the same gooseneck trailer:

Model FMAX212 Gooseneck Trailer

Model LPD Dump Trailer

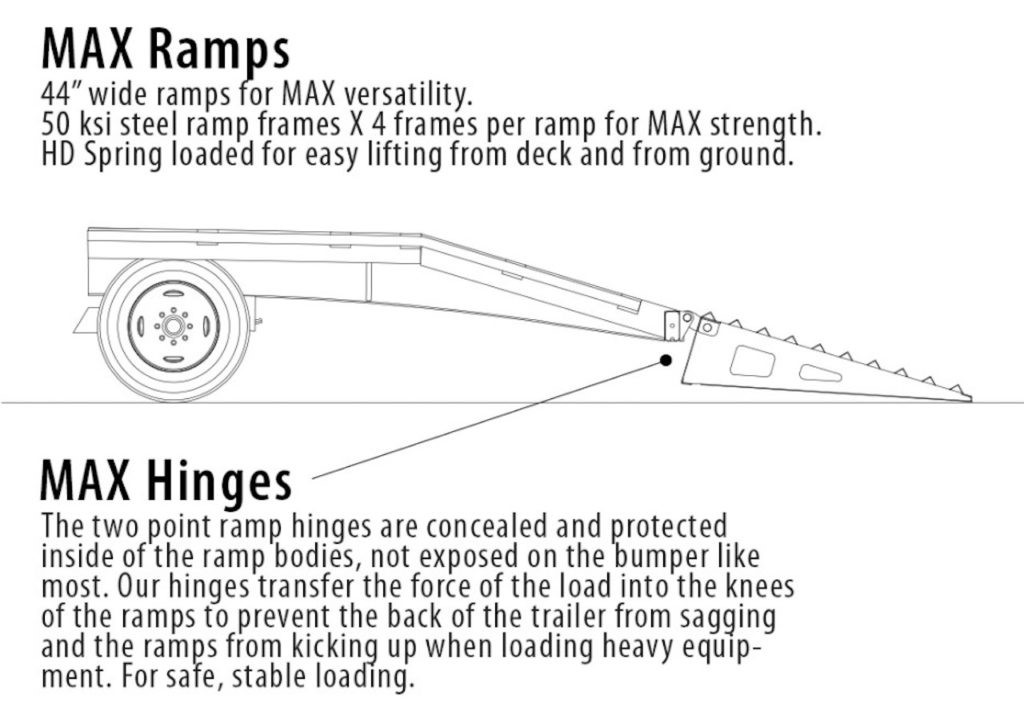

MAX RAMPS

Diamond C's unique Max Ramps are designed with versatility in mind. They can be stowed flat to provide an unobstructed loading surface, allowing the end user to use the full length of the bed to haul longer material. They can also be stowed in an upright position for added security & stability for equipment being transported on the dovetail.

From the materials used to the design of the springs and hinges, Diamond c Max Ramps are unlike any other two wide ramp system on the market. The two-part hinge system (one inside the body and one outside the body) distributes weight while loading and helps to prevent the ramps from kicking up or the dovetail from sagging.

FEATURES

- 44″ wide ramps for MAX versatility (37″ wide on model LPX)

- Self cleaning dovetail

- 50 ksi steel ramp frames x 4 frames per ramp for MAX strength

- HD Spring loaded for easy lifting from deck and from ground

- Aggressive angled cleats for traction in the slickest conditions

When in the stowed position, Max Ramps provide a flat, unobstructed loading surface, which allows you to the use full length of the trailed bed to haul longer material. Max Ramps can also be stowed in the upright position during transport if you have equipment with a pull behind mower for example that needs to be transported on the dovetail. Max Ramps provide a safe and stable full-width loading experience.

Enclosed Trailers

Enclosed Trailers

Flatdeck Trailers

Flatdeck Trailers

Utility Trailers

Utility Trailers

Dump Trailers

Dump Trailers

Ag Transports

Ag Transports

Horse & Stock Trailers

Horse & Stock Trailers